picked up a viair 100% duty air compressor, 450C complete with onboard air kit.

Fitted it earlier this week. took longer for me to do than expected. More down to finding right location and getting some extra fittings.

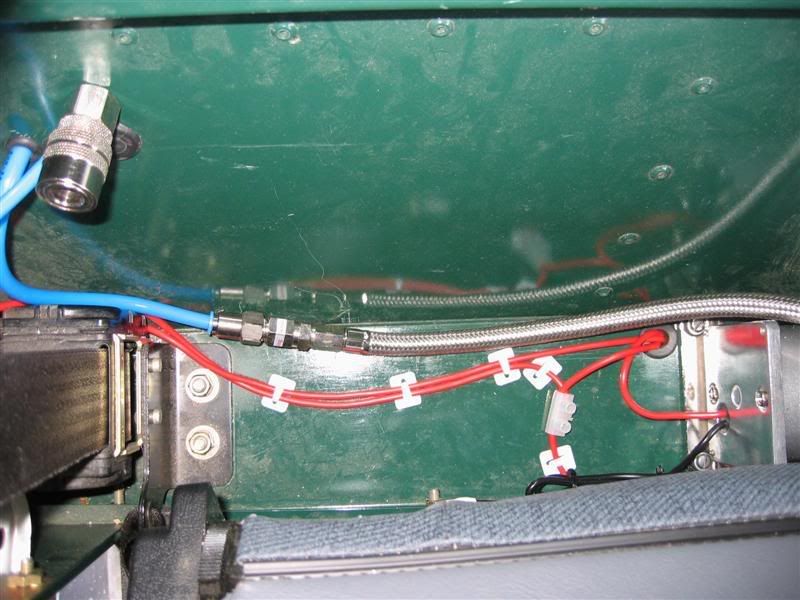

The compressor is dust and moisture resistant but not waterproof so I decided to fit it inside. I had an arb compressor in the back of the hybrid and found that it got in the way so this time I fitted it behind the drivers seat.

I also fitted the guage and on-off switch there too to keep all power cables as short as possible. The compressor draws max of 19A.

I located the tank under the drivers seat as the TD5 has it's fuel tank at the rear. I replaced the standard 6mm compression fitting with right angle push-on types. I find these easier to work on and the right angle put less strain on pipe.

It tucks up out of the way well, but I think I'll replace the drain plug with a blanking plug so that it doesn't get ripped off..

Having the guage nearby meant that wiring was simple. Unfortunately the lead hose fitted to compressor was not long enough to reach the tank so I got some 8mm push-on fittings and 8mm pipe to extend it..

I also fitted the female output fitting here too. This allows easy access via drivers door or I can also pull it through passenger door and reach both nearside tyres.

Again, keeping everthing in one place kept plumbing to short runs..

When I get a rear locker I'll change out combined pressure switch/relay to an 85-105 psi one. The current one is 150psi and it's a straight swap.

Cheers

Steve